Business

Release TIme:2019-05-06

Release TIme:2019-05-06

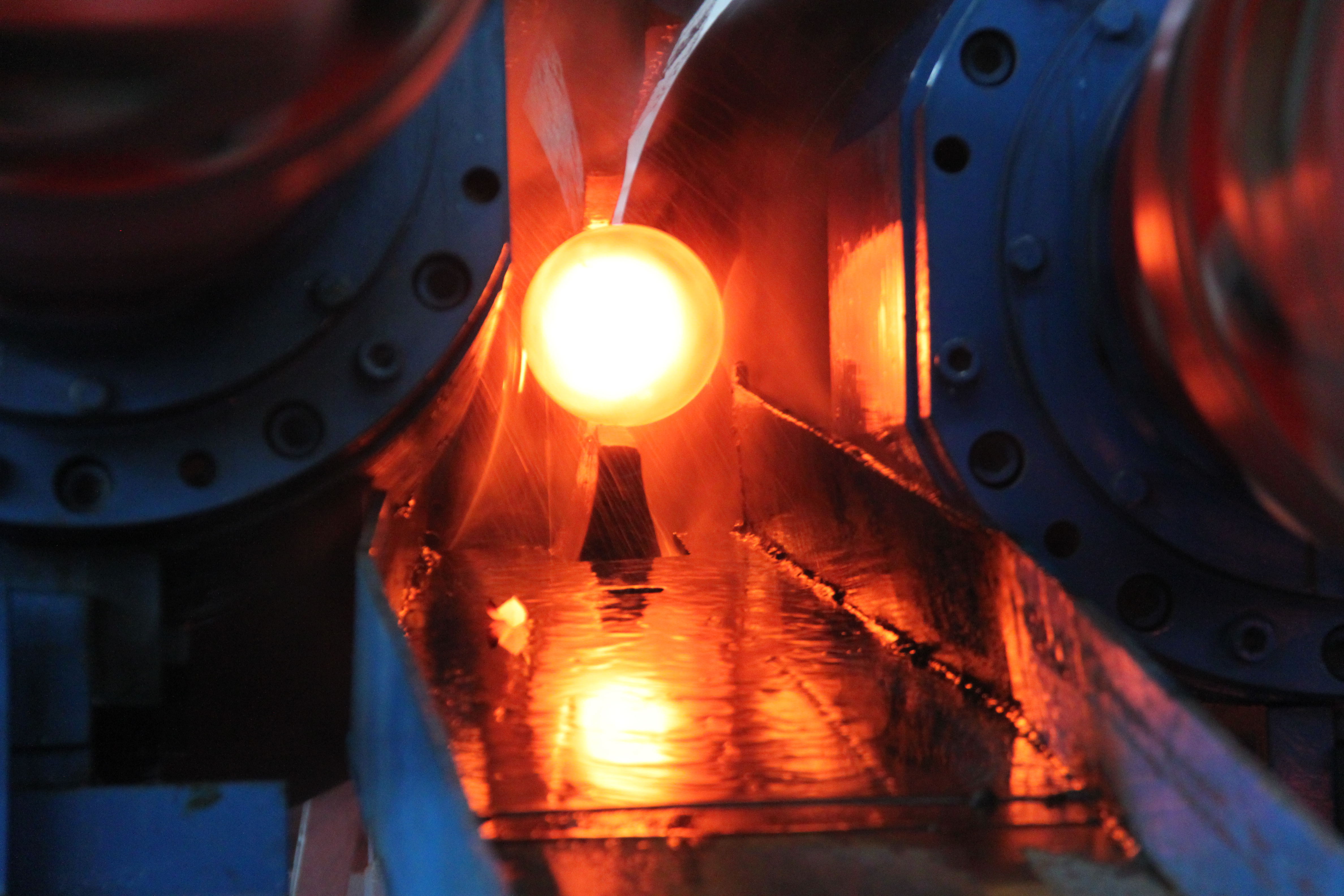

The skew rolling process is composed of heating, rotary cutting, and roll forging. Compared with traditional cast and forged process, the skew rolling efficiency will be increased by 20-30 times. The surface hardness of the steel ball is up to HRC58-65, the volume hardness is up to HRC56-63, the hardness distribution is uniform, the impact toughness is greater than 15J/cm², and the crushing rate is less than 0.5%.

In large-scale metal mining processes, Skew rolled steel balls have replaced traditional cast steel balls and have become the main grinding material for large-scale semi-automatic mills.

Our customers come from all over the world, such as: Australia, South Africa, Ghana, South Korea, Canada, the United States, Finland and so on.

We provide wear-resistant material solutions for Minmetals Mining, Shandong Gold, Zijin Mining, China Gold, BHP (BHP), Codelco, Vale, OT and many other world-renowned mining groups.

In addition to providing a full set of production equipment, we also have an annual production capacity of 100,000 tons of steel balls. Therefore, we have both mature machining capabilities and complete production technology, which can help customers solve various problems in installation and production.

We provide 20mm-40mm, 40mm-60mm, 60mm-80mm, 80mm-120mm, steel ball production lines.

Technical specification

|

Size

Item |

20 |

30 |

40 |

50 |

60 |

80 |

100 |

120 |

|

Steel ball Diameter (mm) |

15-20 |

20-30 |

30-40 |

40-50 |

50-60 |

70-80 |

90-100 |

110-120 |

|

Roller diameter (mm) |

140 |

220 |

260 |

300 |

340 |

450 |

600 |

690 |

|

Roller tilting angle (degree) |

0-5 |

0-6 |

0-6 |

0-8 |

0-6 |

0-8 |

0-7 |

0-7 |

|

Rolling speed (rpm) |

65 |

110 |

80 |

72 |

72 |

64 |

50 |

40 |

|

Motor power (kw) |

30 |

40 |

90 |

130 |

180 |

450 |

650 |

1000 |

|

Machine weight (t) |

2.0 |

3.0 |

8.0 |

10 |

20 |

30 |

50 |

110 |

Video:

Reference

High temperature state ball

Ball in the mold

Final product