Business

Release TIme:2019-04-02

Release TIme:2019-04-02

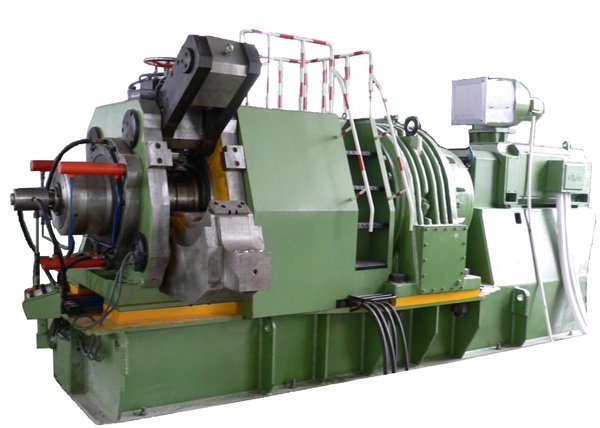

Technology of Continuous Extrusion and

Cladding:

Continuous

Extrusion: The feedback is pulled to the groove by the rotating wheels. With

huge friction generated, the material is forced to flow through the arc shaped

passage. Under high temperature and pressure, the metal is extruded through the

various dies and become profiles or tubes.

Copper Extrusion Production Line:

·Application & Advantages

·For the production of copper flat strip, copper bar, connect, trolley contact wire, and other solid copper conductor.

·Feedstock can be pure copper and copper alloy

·Neither heating nor annealing process, less energy cost

·Smooth surface, no peel and small stick defect, high electrical and insulation capability.

·High quality product resulted by the

hot deformation, solid dense and fine crystallization

·improve the

performance of the product.

Specifications:

|

Model |

TLJ250 |

TLJ300 |

TLJ350 |

TLJ400 |

|

Wheel Diameter (mm) |

250 |

300 |

350 |

400 |

|

Motor Power (KW) |

45 |

90 |

160 |

250 |

|

Feedstock Diameter (mm) |

8.0 |

12.5 |

16.0 |

20.0 |

|

Max. Product Width (mm) |

14 |

30 |

65 |

170 |

|

Product Section Area (mm2) |

5--50 |

10-150 |

30-400 |

100-2000 |

|

Output Rate (Kg/h) |

140 |

400 |

760 |

1400 |

|

Scrap Rate (%) |

1--3 |

1--3 |

1--3 |

6--9 |